Breaking Reliance on Chinese Drone Parts: Vololand Moves Beyond Localization to Global Exports

From an "Assembly Industry" to a "Core Technology Export Industry": A Turning Point for the Korean Drone Sector

The global drone industry has long operated under a structure heavily reliant on Chinese core components. Key systems—including flight controllers (FC), GPS, ESCs, motors, and communication modules—are predominantly concentrated within the Chinese supply chain. Consequently, drone manufacturers worldwide, including those in Korea, have had limited options, essentially building products around these restricted components. Despite rapid growth, the domestic drone industry has struggled to expand globally due to the limitations of this assembly-based structure.

In this context, Vololand marks a significant turning point that is shaking up the industry structure itself. The company has achieved a rare feat in the history of the domestic drone industry: establishing a self-developed system to replace core Chinese components and successfully exporting these solutions overseas.

"Not Just a Replacement, But a Redesign"

Vololand's strategy was not simply to swap Chinese parts for alternatives. instead, the company designed and built core systems from scratch, including the Flight Controller (FC), GPS/RTK, motors, and ESCs. This represents a fully independent technology architecture.

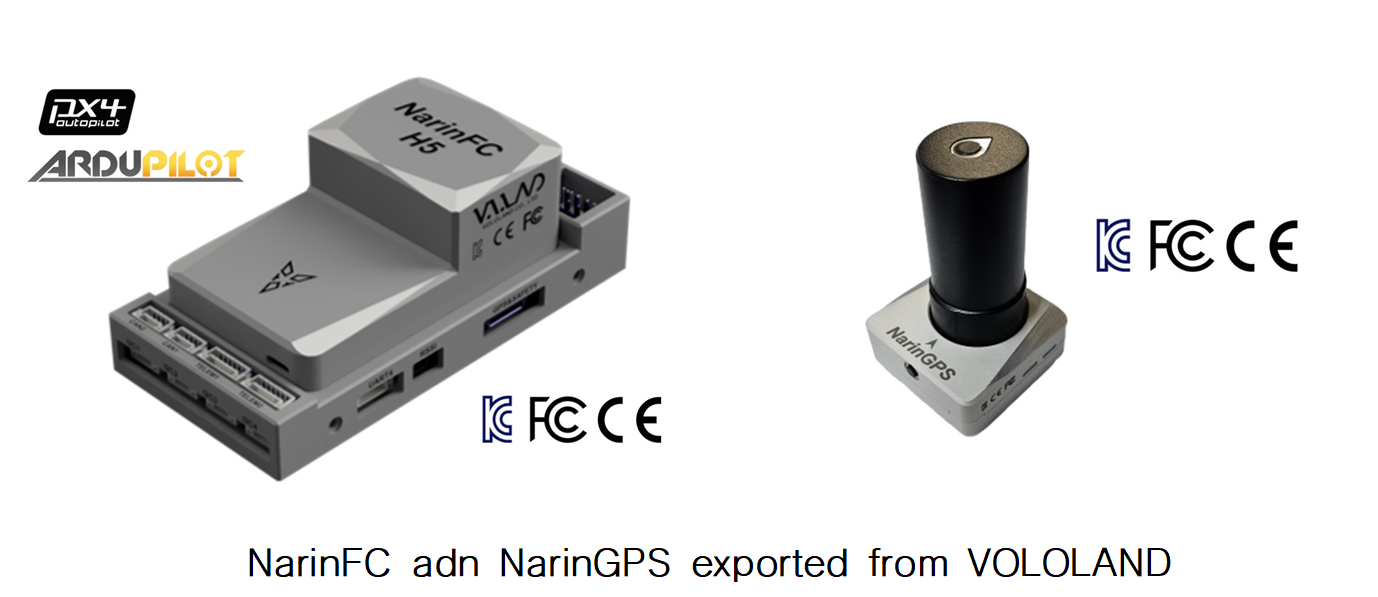

• NarinFC: A flight control platform developed to meet the rigorous demands of the overseas industrial drone market. It features a PX4/ArduPilot dual firmware compatibility structure, industrial/defense-grade reliability, and a triple-redundancy safety design.

• NarinGPS: Secured centimeter-level RTK precision and a structure resistant to radio interference.

These designs were created with long-distance operational environments in mind. This is not merely about localizing parts; it is about setting a new domestic technology standard that breaks away from the China-centric product structure.

Opportunities Created by Global Supply Chain Restructuring

The global drone market is undergoing rapid restructuring due to issues regarding security, data sovereignty, and supply chain stability. The use of Chinese drone parts is increasingly restricted, particularly in the US and Europe, where "Buy National" policies and security standards are being tightened in public and military sectors.

Vololand has turned this trend into an opportunity. By building a technology platform based on an independent supply chain—free from heavy reliance on Chinese products—Vololand offers a vital new option to overseas clients. As a result, the company has succeeded in securing exports for industrial and public drone projects centered on NarinFC and NarinGPS.

An industry insider noted, "Only companies that change their technological structure, rather than simply competing on price, can survive in the current global market. Vololand is the fastest-growing alternative to Chinese products."

Beyond Assembly, Towards a Platform: Vololand’s Vision for the Future

From Localizing Core Components to Becoming a Global Platform Company

Despite its growth, the Korean drone industry has long suffered from the limitations of an "assembly-centered structure," where core components were dependent on foreign products. Vololand chose a completely different direction: shifting from simple airframe production to a platform-based ecosystem.

The company’s strategy centers on the in-house development and platformization of core technologies, including flight control, navigation, propulsion, and communication systems.

"Localization is not the goal; it is the starting point," said a company official. "Localizing parts is only the beginning of competitiveness. Our ultimate goal is to become a technology platform company recognized in the global market."

To this end, Vololand designs and mass-produces core systems such as Flight Controllers, GPS Modules, Motors, ESCs, AI Edge Computers, Power Modules, and RF Telemetry Modules. These are integrated into a single control architecture, forming a scalable drone platform applicable to delivery, industrial, public, and defense sectors.

Building a Self-Sufficient Drone Supply Chain Ecosystem

With the strengthening of "Secure Supply Chain" policies globally, the origin of parts and control of technology are becoming key competitive factors beyond simple performance. Vololand has proactively built a supply chain network based on domestic partners.

The goal is to complete a "complete domestic value chain" by collaborating with domestic companies for frames, propellers, batteries, communication modules, and identification devices. This strategic choice ensures not only cost competitiveness but also long-term supply stability, readiness for public procurement, and security certification.

Vololand Ushers in the Era of Supply Chain Independence with a 100% Domestic Delivery Drone

The Emergence of a Korean Delivery Drone Platform

Amid the accelerating growth of the global delivery drone market, Vololand has unveiled a delivery drone platform based on 100% domestically produced core components (FC, GPS, Motor, ESC).

Market Context: According to MarketsandMarkets, the global delivery drone market is expected to exceed $14 billion in annual sales by 2030, with high growth of over 40%. Major players like Amazon Prime Air, UPS Flight Forward, JD.com, and Meituan are competing for leadership. However, a structural problem remains: reliance on foreign platforms.

Vololand's Solution (VL-1300A): Unlike existing models that often rely on foreign flight controllers and modems, Vololand’s delivery drone overcomes the "assembled drone" limitations. It secures a domestic supply chain for the entire lifecycle—from the core control system to the airframe structure, power, and communication.

Why This Matters: In sectors like disaster relief, military supply, and medical logistics, control encryption and data sovereignty are critical. A system dependent on imported parts risks shutdown due to export restrictions or security issues. Vololand’s independent design ensures long-term maintenance stability and compliance with national security policies.

Conclusion: A Matter of Industrial Security

Experts evaluate Vololand's delivery drone not just as a new product, but as a signal of structural change in the national drone industry.

"Domestic production of drones is not just a technology issue, but a matter directly related to industrial security," an industry expert commented. "Vololand’s ability to develop its own FC, GPS, ESC, and motors is a rare asset in Korea that will be key to expanding into public procurement, defense, and overseas markets."

Vololand is moving the industry from an "assembly industry" to a "platform industry," standing at the forefront of the competition to secure the new global industry standard.